Category: All Posts

Category: All Posts

February is the new April

How time flies. It’s been nearly two years, almost to the day, since I last wrote on this blog. And in 2015, when I posted that story, February was a different kind of month; not just cold, not just bitterly cold, but so cold that we wondered if our vineyard would survive the night. The forecasts said temps could reach minus 13 degrees on the night of February 20, and that was scary.

Vines can survive freezing weather without a problem, especially if they’ve had time to harden off (which requires some cold weather) before the big chill. They can withstand temperatures down into the teens and even below zero. But negative 13 degrees, which is what was forecast two years ago? That’s a killing freeze.

So flash forward to this February. We had two kinds of flowers blooming on our property, and I saw cherry trees and forsythia in full bloom last week. We spent evenings on our deck, not just to enjoy the spectacular weather, but to avoid having to turn on the air conditioning.

And our vines? Well, let’s just say I’m praying for them.

We had some colder weather move in, and the overnight lows were close to freezing. But daytime temps were well above 50 degrees every day, and that’s when vines start coming out of their winter slumber. At some point, the buds swell, then break, and then start sending up shoots. That’s when they’re vulnerable. A late frost in April or, for that matter, a normal frost in March, could threaten much of this year’s crop.

That happened last year. Shortly after budbreak, about the time that the shoots were an inch or so in length, we had two days in which the temperature dropped below freezing in the very early morning, killing a significant share of the primary buds on all of our vines. The secondary buds seemed to survive, and they sent up shoots. But those buds aren’t even remotely as fruitful as the primary buds.

We lost most of our crop. We might have had 35 gallons of wine in 2015, and perhaps 20 percent of that in 2016. Other vineyard managers i spoke to around the state relayed similar experiences.

So, what to do? Well, there are lots of ways to protect vines from late frost events, most of them very expensive. Some vineyards light fires, others spray water over the vines. (When water freezes, it releases heat. The only problem is that you need to spray water for the duration of the frost event.) Other vineyards rent helicopters to fly over the vines, forcing warmer air down. Of course there are only so many helicopters available on any given night, and they aren’t cheap. Maybe for our small hobby vineyard we could buy a big drone to fly over the vines.

As it happens, the annual winter technical meeting of the Virginia Vineyards Association began last week, and the unseasonably warm weather was a definite topic of conversation. In fact, one of the sessions was all about using sprays to combat late frost.

Michela Centinari of Penn State University discussed two in particular: Amigo oil, which can be used to delay budbreak, and KDL, which may lower the freezing point of vine cells. Both approaches seem promising, and I think we might lay in a stock of KDL for next year.

But for now we have one more trick up our sleeves that could work – late, or delayed pruning.

Each year, while the vines are still dormant, we prune to get them ready for the growing season. We mostly use a technique called cane pruning, which involves taking a shoot from the previous season and laying it down on the fruiting wire. That shoot, now a cane, will send up new shoots that will bear fruit.

The second, which we employ on some vines, is called spur pruning. Instead of laying down a new cane, we trim the shoots on the old cane to two or three buds, each of which will send up a new shoot that will bear fruit. Some will get pruned off during the growing season.

What’s important here is that the process of pruning stimulates growth. Many vineyards have begun employing a process known as double pruning, in which they trim away the clutter during the winter, saving the final pruning until later in the Spring, when they hope the danger of frost is past.

Obviously, that’s a very labor intensive approach, and not every vineyard can double prune. But we’re managing some 225 vines, and they can be pruned in a couple of days. So, we can afford to wait.

So that’s our approach for this year, and probably every other year going forward. If February is the new April, then procrastination is our new friend.

The Big Chill — We Felt it through the Grapevine

It takes years of hard work to establish a vineyard, but only one bad night to lose it.

A week ago Wednesday, I thought that night was upon us. With subzero temperatures in the forecast, it seemed as though we might have been on the verge of losing our little hobby vineyard, which has been the focus of so much of our time and energy for the past four years.

To jump to the end of the story for just a moment, we spent a long day working in the vineyard on Thursday and a long night of checking the temperature on an hourly basis and begging the climate gods to show some mercy. And when I climbed out of bed Friday morning, I was feeling much more optimistic. We won’t know for sure until later in the year, but I believe that our vineyard survived, though not without some degree of injury to the vines.

We had known for several days that severely cold weather was on the way, but it had seemed as though it would be manageable. We monitor a number of weather services – WxRisk, Weather Underground, and the Weather Channel among them – and the latter two provided forecasts that varied daily. (They also vary between each other. Sometimes I pick the one I like best and lull myself into a false sense of security.)

So, the outlook for early Friday morning looked very different on Wednesday than it had only a few days earlier. Negative five degrees had been scary enough. But I was really surprised to see forecasts that warned of temperatures as low as minus 13 degrees Fahrenheit.

Now, our vines can do just fine in freezing weather, and they’ll even manage through sub-zero temperatures. At some point, though, you can expect injury. Everything I’ve read – I’ve never experienced it, but I’ve done a fair amount of reading – suggests that at negative five degrees we should expect to lose at least some of the buds that would produce shoots and grapes in the coming growing season.

And at negative 13?

Well, the damage could be catastrophic. Buds are more sensitive to the cold than trunks and canes, but only by a few degrees, according to Virginia Tech’s Tony Wolf, who was good enough to put out an alert Wednesday with lots of information about the effect of freezing weather on vines.

Losing a significant number of buds and part of next year’s harvest would be bad news. But it’s one thing to lose part of the crop and quite another to lose the entire vine. At some temperature, the scion – the actual vine, which is grafted onto rootstock – could be killed. If that happens, there’s little alternative but to replace the vine.

That would be disastrous for anyone, and my heart goes out to commercial vineyards that might have lost either a substantial portion of the 2015 crop or some part of their vineyard. For them, it’s everything. For us, it’s a hobby, not our livelihood, so it would be incredibly self-centered for me to complain too much about our potential loss.

Having said that, though, the prospect of losing vines hit me on a very personal level. We’ve spent more than four years getting to this point, and I feel like I remember almost every minute of the hard work and sacrifice.

But forget, for a moment, about the time we spent taking classes, reading and talking to vineyard managers to learn everything we could about viticulture. And forget about the cash outlays. Let’s also put aside the hours of physical labor that went into establishing the vineyard. (Well, not too far aside – I can still remember a day last summer, working five hours with a backpack sprayer and thinking I was just about ready to die by the time I finished.)

As important as all those things are, what matters most to me is the time – the number of years it takes to order vines, plant them, and nurse them through to their first harvest. We all have only so much time in this life. And that means we get only so many chances to get it right.

So yes, we could start over again. We could order vines, but we wouldn’t be able to get the vines we want this year, so we wouldn’t be able to plant until the spring of 2016. And it would be another three growing seasons before we harvest again. That would bring us to the fall of 2018, which seems like forever.

We did have a couple of things going for us. First, we had a couple of weeks of freezing weather leading up to the big chill, which helped harden off the vines. That meant they should have been able to withstand lower temperatures than would have been the case if the deep freeze had hit all at once.

Second, we had a blanket of snow on the ground. Snow has an insulating effect, and if it’s deep enough, it can protect the graft union, where the scion is joined to the root stock. In our first two years, we had hilled up around the vines, creating a mound of dirt a couple of inches above the graft union to provide the same kind of insulating effect. This year, with the harvest and all of the time and labor that goes into fermenting five different varieties of wine, we just didn’t get to it. Lesson learned.

Third, we’ve planted varieties that are reasonably cold-hardy, including Cab Franc, Petit Verdot, Petit Manseng, and Viognier. The exception is Merlot, which is much more sensitive to cold injury. The Merlot is also the youngest of the varieties we planted and therefore the least able to take winter’s punch.

For all that, though, we were pretty worried. By the end of the day Wednesday, the Vineyard Goddess and I had decided to spend Thursday doing everything we could to protect the vines. Our plan was to use mulched and partially composted leaves and grass to hill up around each vine, in the hope that we could insulate the graft union to the point that we could save the vine, if not this year’s harvest.

We traveled to Afton Wednesday night so that we could get an early start the next morning. Sometime around 8 a.m. Thursday we made our first foray into the vineyard. It was about 3 degrees above zero and the wind was blowing. I was colder than I think I’ve ever been in my entire life, and we went back inside to add a couple of layers of clothing, have a cup of coffee, and wait for the temperature to reach a more civilized 6 degrees or so.

By 9 a.m., we were working in earnest. Over the years, I had dumped a large volume of leaves and grass clippings into a heap on the other side of our property, and we had a very large pile by this point that was just waiting to be repurposed. I used the front-end loader on my tractor to haul them into the vineyard where the VG mounded them around each vine. Here and there we added some snow to pack the mulch down, but mostly, we relied upon the organic matter to insulate the vine.

The overnight temperature readings were somewhat milder than the forecast, but they were still pretty severe. At 7 a.m., the temperature hit minus 6.1 degrees, according to the Weather Underground station closest to us. I would have preferred to have our own weather equipment in the vineyard, but this station is not only close, it’s also at the same elevation as our vineyard, so I expected that the readings would be very close to what we would have gotten if we had a thermometer on our own property.

In the next week or so, we’ll be sampling buds and canes to see how well we survived the big chill. This is a first for us, and I have no idea how we did. But I can say this: I feel a whole lot better because of the work we did. Even if we lose the vineyard – which I think is a low probability outcome – I’ll feel better knowing that we did everything we could. If we had done nothing at all and lost only half the vineyard, I would feel much worse.

Wine grape growing is agriculture and like farmers everywhere, we live at the mercy of whatever Mother Nature throws at us. As Chris Hill, one of Virginia’s vineyard pioneers, told me during one of our classes – and this is a major paraphrase – the averages (temperature, etc.) are important, but it’s the records that kill you. And this year was one for the books.

You Never Forget Your First Crush

Scott Elliff of DuCard Vineyards once told me that harvest was a joyous time, the culmination of a year’s hard labor tending the vines. And on September 21, after four years of planning, preparation, and hard work, we experienced that joy in our own vineyard, picking grapes from the vines we had planted with our own hands and nurtured like our own children. If I’m at this ten years from now, I’m sure I’ll still find joy in the harvest, but I doubt that it will be anything like the euphoria I felt as we picked those first Cab Franc grapes this year.

To recap a bit, the Vineyard Goddess and I began this adventure some four years ago. We took classes on viticulture and enology at Piedmont Virginia Community College, did lots of research on our own, debated which clones and which rootstocks to order, and finally planted our vineyard in the (very) early spring of 2012. Since then, we’ve invested a lot of sweat, a couple of tears and even a little blood (I snipped my finger with the pruning snips during the harvest) in bringing those vines to the point where they were ready to produce a crop of grapes worthy of picking.

And, oh my God – did those vines ever produce!

The Cab Franc and the Petit Verdot were absolutely magnificent: nearly perfect fruit that proved irresistible to the bees that laid siege to those rows of vines. The Merlot, for whatever reason, fell behind. I had thought we’d pick the Merlot first among the reds, and by all rights we should have. But after accumulating sugar at a rapid pace, the Merlot vines just shut down. We picked them October 5, and I’m hoping for the best.

The Viognier was disappointing. Virginia-grown Viognier makes a wonderful wine, but it’s hard to grow. For some reason it’s subject to something called primary bud abortion, and I guess our vines experienced that phenomenon, because the Viognier was the least fruitful of all our varieties. The grapes looked lovely, but I had expected about 100 pounds or so, and we got about 20. Other vineyards around the Commonwealth had the same experience, though on a totally different scale (the difference between tons and tens of pounds).

The last of our varietals is Petit Manseng, and those grapes looked beautiful when we harvested them two weekends ago. We want to make a desert wine from them, and so we let them hang a bit longer than we might have. We had hoped they would accumulate a little more sugar and lose a little more acid. If we had known we were in for some pretty significant rain the week prior, we might have chosen differently, but weekend vintners like us have to make some tough decisions and then live with them. As it turned out, we didn’t get the extra sugar or the lower acidity. We’ll work with it.

But getting back to where I started, there are some things you never forget. I can still remember the first crushes of my life – the first time I saw the Vineyard Goddess in the newsroom of our college newspaper, the first book I really fell in love with (thank you, James Joyce), the first time I saw my children, and the first time I saw Venice, walking out from the train station on a beautiful sunlight day to see the Grand Canal sparkling with life. Some things you just never forget.

And so, I don’t want to get too sentimental about this, but when we had finished picking the Cab Franc on that beautiful September morning, the VG and I hugged and felt a sense of euphoria. All those years, all that sweat, and all that worry behind us; now we had the fruit of our labor in front of us, collected in a dozen five-gallon Home Depot buckets. It was one of the most wonderful moments of my life.

A little detail: we had gotten up at first light that morning to pick, and we finished before the sun hit the vines. The early morning, especially this time of the year, is cool, and you want the grapes to hit the crush pad (i.e., our driveway in Fairfax) cool. The crush, by the way, is the term applied to the harvest and the process of preparing the grapes for fermentation.

As we picked, we stored buckets in a refrigerator we had purchased just for this task. With the shelves removed, we could fit six buckets, stacked on top of each other, separated by the shelves I had pulled out and repurposed. As we brought more grapes up from the vineyard, we pulled the buckets from the frig and dumped them into a 120 quart cooler from Costco. When it was filled, we pulled out smaller coolers. The grapes were cool to the touch right up to the crush, and the must came in at around 60 degrees or lower.

As it turned out, picking the grapes was the easy part. I had done a lot of research and reading, a lot of planning, and a lot of online shopping for the equipment and supplies we would need. But for all that work, when it got down to actually making the wine, I found myself in the weeks before the harvest feeling a bit lost.

A refrigerator full of wine grapes — this is about half the load of Cab Franc. We dumped these into the cooler and refilled the frig.

So, before we picked the first grapes, I started making a cheat sheet. It went something like this:

First, add sulphur at a rate of 50 parts per million (.33 grams per gallon), which kills off unwanted natural yeasts and protects the must (the mix of juice, skins, seeds, and stems that will turn into wine) during those vulnerable hours before fermentation begins. Next, check the brix, pH and TA (titratable acidity) of the must (add a dozen steps here). Rehydrate the yeast (add a half-dozen steps here). And so on. (Add dozens and dozens of individual steps.) And for all that, I found myself furiously reading the instructions (again) on my lab test equipment to be sure I knew how to test the TA, and reading other literature on hydrating and preparing yeast.

When we arrived back in Fairfax, we started with the easy stuff: the sorting table. We had purchased a folding table, which turned out to be the perfect place for the family and friends to gather around for some work and talk. Kind of like what I imagine a quilting bee was like a century or so ago. We pulled some chairs around the table, and the VG and I, plus daughter Kate and a couple of neighbors, sorted the grapes. That’s easy and straightforward, but it’s also very time consuming.

The fruit was amazing, so we didn’t throw away very much at all. Mostly, we were looking for MOG – matter other than grapes. We found the occasional spider web (with the spider, in most cases, which elicited a few screams), and some extra leaves and such. But the fruit that went into the crusher was just about perfect.

The crusher-destemmer was way more of a machine than we really needed. It crushed the fruit faster than we could drop it in, and we were finished with that part of the process in maybe ten minutes. Honestly, cleaning it took way longer than the actual crushing. But I’m still glad I bought it. More on that in another post.

In the end, the Cab Franc yielded some 20 gallons of must – juice, grape skins, seeds and some stems that fell through the destemmer. As luck would have it, I had a 20 gallon bucket on hand to catch it all. Again, we’re still on the easy part.

I weighed the sulphur (potassium metabisulphite), mixed it with distilled water and added it to the must. And then, I spent hours measuring the pH and TA and brix, deciding whether to adjust the sugar level or acidity (I decided not to), and preparing to pitch the yeast. And in between, I cleaned out the crusher, the extra buckets, and everything else I used in the process. Not to mention sanitizing everything that came into contact with the must.

I have always used potassium metabisulphite for sanitizing, but now, with my own grapes at stake, I worried a bit. I had used sulphites at 50 ppm to protect the must, and the mix for the sanitizing solution was much stronger than 50ppm. So I decided to go with Star San, an acid-based sanitizer that requires no rinsing afterward. Pretty much every bone in my body was calling for sulphur, but I resisted.

It was some day. We were in the vineyard at about 7 a.m., and it was close to 10 before I pitched the yeast, which started the fermentation (Not right away mind you; no, the yeast played with me, waiting days before they actually began to ferment the must).

Much of the time spent that day involved nothing more than anxiety – wanting to get everything just right and worrying that I was getting everything just wrong – but another part of it was the actual physical labor involved. By the time the day was over, I was exhausted, and the memory of hugging the Vineyard Goddess at the end of the harvest was just that – a distant memory.

Well, I suppose in the end, it’s like dating the first girl you had a crush on – the hopes, the anxiety, the desire to get everything just right, the certainty that you have gotten everything totally wrong, and the physical exhaustion that comes from working so hard.

But I’m hoping this crush is like the time I laid eyes on the Vineyard Goddess for the first time. If this crush is as perfect as that one, we’ll have a wine for the ages.

Preparing for the Harvest – Part II

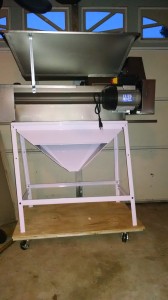

The bladder press is a lovely piece of equipment. below the juice channel, you can see the hook-up for the garden hose.

After three years and more of work and study, we’re close to our first harvest. We started in 2010 with our first classes on viticulture at Piedmont Virginia Community College, and moved on to researching and ordering vines in early 2011. We’ve spent three y ears nursing those vines along, and now some of the varieties – the Viognier especially – are only days away from being ready to pick. (With the rest a bit further behind.) And for all the time we’ve had to think about these things, found myself scrambling in these last few months to make sure I knew what I was doing and had the equipment to do it with.

In some ways, assembling the small items – the yeasts, the beakers, the malolactic bacteria and the like, which I discussed in my last post – was the easiest part of assembling a home winery. Those items mainly required research and an hour or so on the More Wine site. The big items – the crush-destemmer, the bladder press, and the barrel room – though few in number, posed the biggest challenge.

Because they were the most expensive items I ordered, I spent quite a bit of time agonizing over the crusher and press. There are lots of choices at very different price points, and I wanted to order equipment that would be adequate for the task without going overboard.

The crusher destemmer has two tasks. First, it gently crushes the grapes, so that, in the case of reds, they are ready to begin fermentation, and, in the case of whites, they are ready for the press. Second, it separates the stems (which contain bitter tannins) from the grapes. The stems fall out through one side of the crusher-destemmer into a bucket, and the grapes and juice fall into a fermenter.

I would have preferred that it work in the opposite order, first so that there’s no risk of the stems being crushed, and second, so that the two processes could be separated allowing me to destem without crushing if I chose to. But that’s a whole different price range, and all in all, I’m pretty happy with the motorized, stainless-steel machine I purchased. I did wonder briefly if it was overkill for the quantity of grapes I’m likely to be processing, but I tell myself that it’s an investment in the future. Yeah, that’s the ticket, an investment in the future!

I also ordered a bladder press, which is used to press the juice off the skins and seeds of the grapes. The bladder press is pricier than the more traditional-looking basket presses (think wood stave sides and a ratchet handle at the top that is turned to push down a plate to squeeze the grapes), but all of the literature I’ve read suggests the bladder press is a much better choice. The bladder inside the press fills with water from a garden hose to expand gently, pressing the grapes against a screen that lets the juice flow out, while the skins are kept inside. It’s actually quite a beautiful piece of hardware.

After I unpackaged the crusher-destemmer, admired it, let it sit on the shipping pallet for a couple of weeks (it’s really heavy), I came face to face with a small mistake. I hadn’t ordered a stand for it, reasoning that I could use sawhorses or something similar to hold it high enough to let the crushed grapes fall into a fermenter.

Inside the bladder press – the bladder at the center fills with water and expands to gently squeeze the grapes.

Well, not quite. It turns out the crushed grapes fall through the entire length of the bottom of the crusher, and need to be funneled into some kind of container, either a small fermenter or buckets to carry the grapes to a larger fermenter. So, I turned back to MoreWinemaking, which is where I bought the crusher to see about a stand. It cost $325, which isn’t terrible, but it would have cost nearly as much to ship it, since it has to go by truck. That just seemed wrong, somehow. I had paid one shipping cost for both the crusher and bladder press, and while the shipping was expensive, it was still only a fraction of the cost of the two pieces of equipment. In the case of the stand, I just couldn’t bring myself to pay as much for shipping as for the item itself.

So, I tried other vendors, and the story was the same everywhere, until I stumbled across Carolina Wine Supply. They were willing to ship it UPS or FedEx, unassembled in a flat box, for something like $25. Definitely a company I’ll be doing more business with.

For what it’s worth, having equipment shipped by truck isn’t exactly a trouble-free process. They really want to ship to businesses with loading docks, not to suburban homes, and the cost goes up significantly for the latter. Moreover, they expect you to make arrangements to be there when they arrive, which can be difficult because they don’t always provide much advance warning. I was able to bargain with the trucking company to leave the items on my driveway while I wasn’t home, which worked after a couple of false starts, but it did mean I waived my rights to inspect the items for damage. Well, you work with what you got.

At some point over the summer, I began to wonder where I would store the wine while it was fermenting and aging. Once the initial fermentation is complete, the wine goes into glass carboys for secondary fermentation and, later, for aging. I have quite a number of glass carboys, and it occurred to me that spreading them across the garage wasn’t practical.

A six gallon glass carboy is heavy to begin with, but once full, it weighs an additional 48 pounds, so moving a full carboy around is physically demanding and mentally harrowing. If it slips from your hands and breaks, you end up with a garage full of spilled wine and broken glass. Not good.

So, I’m constructing a garage “barrel room” that should be large enough to hold 15 six galloncarboys on three shelves, plus either large plastic fermenters, small oak barrels or more carboys on the floor. The shelves are installed at a 15 degree angle, which makes it easier to insert a wine thief or racking cane into the back shelf. By using a pump to move wine, I’ll never have to lift a full carboy.

The very top shelf will hold an assortment of one gallon jugs, supplies etc., and a 5,000 BTU air conditioner mounted near the top will keep it cool inside. I have most of the inside finished, but need to build the doors and mount the air conditioner.

I’m pretty pleased with the way this home “barrel room,” looks, and I have to credit Steve Hughes’ book,The Homebuilt Winery. The book includes the plans, but fair warning, the average person will probably want to spend some time studying and interpreting the plans. I’ve done a lot of home construction projects in my time, and I have a pretty complete workshop, but I still found some parts of these plant to be a chore to figure out. So, while I like the book a lot, I wish it had provided a bit more detail for some of the projects.

However, the idea for the barrel room was worth the cost of the book, and the plans were adequate to get me through the project. The book also gave me the inspiration to build a dolly to move the crusher-destemmer around, and there are a few other projects that I might eventually take on. For the really ambitious, he shows you how to build your own ratchet press and destemmer, and a dozen or so other things. All in all, it’s a book I’d recommend for the aspiring Garagista.

We’re hoping to harvest Viognier in just a few days, though with rain in sight, that may not happen. Hopefully the grapes have another week in them before they start to become over-ripe. I was thinking of picking last week, but the brix (sugar level) was at 21, a few points lower than I wanted. The decision on when to harvest is based on lots of things, including ripenesss and the weather forecast, and you don’t always get the perfect combination. Waiting can be stressful, and it was hard to resist picking those Viognier grapes last week. A friend at a nearby winery counseled me to wait and deal with the stress, adding, “don’t lose your nerve!”

Well, I haven’t. At least not yet!

Preparing for the Harvest

The harvest is here, or at least it’s close. Our Viognier grapes should be ready to harvest next week (I had thought a week ago we’d would have harvested yesterday), and the Merlot and Cab Franc won’t be far behind.

So, I’ve been scrambling over the past month or so to get ready. With a few notable exceptions involving John Updike, virtually all of my reading lately has involved winemaking. And the free time that I haven’t devoted to reading about wine chemistry or winemaking techniques have been spent assembling the equipment and supplies I need to make wine.

And it seems that I need a lot. I think the average cost of a bottle of wine from this vintage will approach the price of a bottle of Chateau d’Yquem. There’s a part of me that wonders if it wouldn’t have been smarter to have spent all that money buying someone else’s wine. But really, where’s the fun in that?

The learning curve has been pretty steep, and I’ve made a bunch of mistakes — even though I have yet to harvest my first grape. After learning all about free and bound SO2, pH, fining and a hundred other things, I realized I was all but clueless on a number of practical matters, such as which yeast to use for each grape variety. For hobbyists like me who are buying yeast in quantities of 50 to 80 grams at a time, the options are more limited than they are for commercial wineries that are turning out tens of thousands of cases of wine. But that’s a relative thing. There are still 40 or 50 different yeasts available in small quantities from companies like More Wine and Midwest Supplies.

I still remember a class at King Family Vineyards where winemaker Matthieu Finot invited us to taste wines from three different barrels. They were all distinctly different, and I was truly surprised when Matthieu told us that they were all made from the same grape variety from the same vineyard bloc and vintage, and that the only difference was the strain of yeast he had used. Clearly, yeast matters!

The Vineyard Goddess and I went to a lot of trouble to pick what we thought were exactly the right clones for each of the grapes we planted – and some of the clones we wanted were not easy to get – and the right root stock as well. So, it only made sense that we should go to the same lengths to get the right yeast. After lots of reading and lots of anxiety, I selected Rhone 4600 for my Viognier (and I think also for the Petit Manseng), Bordeaux Red (BDX) for the Petit Verdot, MT for the Merlot, and BM4x4 for the Cab Franc. And then, on reflection, I ordered something called BA 11 for the Viognier, even though I already had the Rhome 4600. Here’s the writeup on More Wine‘s web site for the BA 11:

BA11 was selected in 1997 near Estacao Vitivinicola de Barraida in Portugal. It has excellent fermentation kinetics, even at low temperatures. It promotes clean, aromatic, estery characteristics during fermentation. BA11 intensifies mouthfeel and augments lingering flavors in both still and sparkling white wines. BA11 encourages the fresh fruit aromas of orange blossom, pineapple and apricot. In relatively neutral white varieties BA11 brings out tropical fruit, cream, vanilla and spice. With fruit from hot climates, BA11 can really help to “flesh out” a wine by its’ volume and mouthfeel enhancement. This strain is good by itself, as well as being a great structural component to a blend. Best results from 50 to 77 degrees F, and alcohol tolerant to 16%.

Sounds pretty good, right? Well, for now. I’ll probably wait until I’m running the crusher before I settle on the yeast. Oh, and I still haven’t decided which yeast strain to use for the Petit Manseng. Maybe the Rhone 4600? Well, I was feeling pretty good about the future of my wine when I realized I hadn’t yet ordered malolactic bacteria, the stuff that converts tart malic acid to softer lactic acid, generally just in red wine. Not to worry. I went back to the More Wine site, did some research, and ordered enough ML bacteria to soften an ocean of malic acid. Well, maybe not an ocean. But at least the dozens or so (yes, I am an optimist) gallons of red wine I will be producing this year. It turns out that ML bacteria packages, once opened, can’t be saved. So for each of the three reds I’ll be making, I had to order separate batches of ML bacteria, at about $33 a pop.

And that’s barely scratching the surface of the purchases I’ve made in the past few months. I’ve accumulated lots of lab equipment, including an instrument that measures pH, sulfur dioxide, and titratable acidity. I bought a high-precision scale, an assortment of flasks, beakers, air-locks and stoppers, and four new plastic fermenters: two that can hold ten gallons of must and two that can hold 20 gallons. I already have a number of 7.9 and 6 gallon fermenters, so I’m feeling ready for a harvest of almost any size. And I’m really praying that I can actually fill at least one of the 20 gallon tanks.

There are also a few additives that are necessary, and some that are not, strictly speaking, necessary, but are helpful enough that I’ll probably try them out. In the can’t-do-without category are yeast foods. There are a few different ones available, both for mixing with the yeast when it’s being prepared for inoculation and for helping the fermentation along in the days that follow, but I settled on Go Ferm and Fermaid K.

Other additives include Tartaric Acid for making adjustments in the acidity of the must, Albumex Bentonite and other fining agents, and oak cubes, which substitute for the oak barrels that I don’t have. I could go on about additives, but I’ll stop here for now. In the next post, I’ll cover the big items, such as the crusher-destemmer and the construction of my garage “barrel room.” For now, though, I’ll close with a short list of the books and online publications I’ve found most useful.

First, I can’t say enough about the folks at MoreWine. In addition to all the stuff they’ll sell you — and they have a well-organized site that includes quality equipment and ingredients at reasonable prices with lots of information — they have a series of free booklets and guides that I would probably have been willing to pay for. The guides to red and white winemaking run nearly 100 pages each, and are full of practical information. In addition, they have guides to SO2, the use of inert gas, bench trials and a number of other subjects. After reading a bunch of other books, I found these manuals provided the down-to-earth practical information I needed to go from the vineyard to the bottle.

David Bird’s Understanding Wine Technology was also quite useful. It provides a good overview of almost every imaginable topic in winemaking, and gets into considerable detail. If you’re wondering how yeast works its magic or what carbonic maceration does, this is a great book. It isn’t the practical, down-to-earth kind of manual that MoreWinemaking provides, but it includes a wealth of information and it’s a joy to read.

David Pambianchi’s Techniques in Home Winemaking is probably the most detailed and thorough book on subjects of interest to home winemakers that I have ever encountered. This is a book that I have perused, rather than read, but I’ve used it to get loads of technical details on topics of interest. I’m thinking it’s a must-have for any home winemaker.

One of my favorite books on viticulture and winemaking is Authentic Wine by Jamie Goode and Sam Harrop. Split roughly in half between the two subjects, this book helped me understand what kind of winemaker I wanted to be. It covers lots of important subjects, like Brettanoymyces and free vs. bound SO2, but it also gets into some of the philosophical issues, like how much intervention in the cellar is okay.

The very first book I read, some four years ago, was Jim Law’s The Backyard Vintner. It doesn’t go into great depth on any subject, but it provides a more than adequate overview of all the important topics in viticulture and winemaking in very accessible prose. Jim Law owns Linden Vineyards, one of Virginia’s great wineries, and the articles on the Linden web site are also well worth reading. (And while you’re at it, check out Jim’s articles in the last two issues of Grape Press, the publication of the Virginia Vineyard Association, as well as an article in the next issue, which should be out by the end of September.)

And finally, the second book I read, just after Jim’s book, was Jeff Cox’s, From Vines to Wines. This is an excellent guide that covers everything from planting your vines to bottling the wine. If you’re not sure how to prune second year vines or how to rehydrate yeast, this book has everything you need.

There are many more books, I’m sure – I actually have a couple sitting on my shelf that I haven’t yet begun to read – on the subject of winemaking, but these should be enough to get anyone started. I wouldn’t say they’re a substitute for classes or hands-on experience, but they’re certainly an important supplement. God knows, I’ve found them invaluable.

Saving Our Grapes from Birds and Other Predators

Last year, as we approached harvest time, I was admiring our grapes one weekend day when I realized it was time to check the sugar levels. Unfortunately, I had left my refractometer in Fairfax, which, well, wasn’t very helpful. But not to worry. I made a mental note to bring it with me to Afton the following weekend, when I was sure that the sugar in the grapes would be just about perfect.

I remembered the refractometer, but unfortunately, I could not find the grapes. I searched the Petit Verdot rows, where I was sure I had seen small clusters hanging, and the Cab Franc rows, which I knew also had grapes hanging from the vines. But there were none to be seen.

It was kind of like the time my car was stolen at the train station in Jersey. I stared at the space where my car used to be wondering why it was no longer there, and then wandered around the parking lot as though I hoped it was magically somewhere else. Somewhere other than where I knew I had left it. Self-delusion is a terrible thing.

My car was gone, all those years ago, and last year, so were my grapes. My first thought was birds. Yeah, they love grapes, and they know when they’re ripe. They descend upon the vineyard just at the time when the brix (a measure of the sugar level) is just right, and they steal everything in sight.

Of course, it could have been other predators. It seems that all of nature has its eyes on grapevines as the harvest season grows near, and so the vineyard manager needs to be alert. Raccoons love grapes, as do squirrels and bears and crows and turkeys. As it happened, our neighbors told us about a bear they had spotted wandering through our property last year, right around the time we found a huge gash in our deer fence. Jim Parkhurst of Virginia Tech told the summer technical meeting of the Virginia Vineyards Association that a bear will sit down in the vineyard, pull clusters of grapes off the vine, and then move down the row, sit again and pull off more clusters.

But, of course, it’s hard to know for sure which predator stole my grapes. Last year was a very difficult year because of the acorn shortage. There are two types of acorns; those that come in every other year and those that come in annually. In 2013, both types failed. So squirrels especially were desperate for a meal, and vineyards were like the free sample aisle at Costco. I talked to vineyard managers who reported losing more than a third of their grapes to predators last year, which is extraordinary.

So, this year, we’re all taking precautions.

This is more or less what the netting will look like once it’s dropped. Here’, I’ve just attached it to the first catch wire on the Viognier vines, and haven’t yet rolled it up.

I spent the day Sunday (after a full day Saturday working with the Vineyard Goddess on canopy management) installing bird netting. Bird netting places a barrier between the grapes and predators, and hopefully it will be enough to preserve this year’s crop. I got about half-way through the vineyard, hanging the netting on my Viognier and Petit Verdot, and then rolling it up so that it will be out of the way until it’s needed.

I should point out that I would have also gotten the netting up on my Petit Manseng except that the Vineyard Goddess had found – I can’t even bring myself to say this – a bird nest in those rows, and asked me to wait a week or two. I wanted to rip the nest out, but I couldn’t. She’s the Vineyard Goddess, after all, and she outranks me when we’re working among with the vines.

As it turned out, I wouldn’t have gotten that far anyhow. I ran out of clips before I was quite through the Merlot, and I ran out of energy before I got to the Cab Franc. So, I ordered more clips today from Spec Trellising, and I’ll be praying next weekend that I don’t run out of netting. The roll that they shipped is 1,650 feet long, which should give me a couple of feet to spare. But who knows.

Here’s what the netting looks like after it’s rolled up, waiting until the grapes are ripe enough to attract predators.

A couple of words of advice to the weekend vintner about installing bird netting. First, don’t expect instructions. Apparently the netting doesn’t come with any. And don’t expect advice on how to install it – I didn’t get much. Also, don’t think the Internet will be of any help. I googled side-netting, bird-betting and every conceivable permutation of those terms for hours and got no help whatsoever. I did find lots of helpful advice, videos included, on different kinds of netting, especially the stuff that hangs over the trellis, creating a ceiling of sorts that you can drive a tractor underneath. But nothing for my side netting.

As it turned out, though, much to my surprise, bird netting isn’t all that hard to install.

Once I got the netting into the vineyard, and looked at the net clips, I was able to figure out (after one false start) how to do it. The clips look like tiny boat anchors, with a hook at the top to hold it to a catch wire and one hook on each side at the bottom. What I finally realized is that the back hook holds the netting on the catch wire permanently, and the front hook holds the rolled up netting (the storage position) until it’s ready for use.

I have lots of other questions, but I’ll figure it out as I go. And I ordered one more piece of equipment – small “C” hooks, which will hold the netting together at both the top and bottom to keep birds from finding a way in. I also have a tagging gun which is supposed to be a good way to zip shut the net at the bottom, but truthfully, I couldn’t figure out how to make the gun work this weekend.

I’m feeling pretty good about the netting, though. Unlike last year, I think most of my grapes will make it through to harvest. And if they don’t, it will be for reasons other than birds and other predators.

And, this is my first real harvest. As upsetting as it was to see my grapes stolen by predators last year, the fact is, it wasn’t that much of a loss. We had dropped fruit during the year to give the two-year old vines a good start in life. We wanted their energy to go toward developing a strong trunk and root system, not grapes. So, for those of you wondering exactly how many grapes were stolen, the answer is something like a half-dozen or so clusters that we missed when dropping fruit.

Not the end of the world, thank God. More like a cheap lesson for the future.

Tempranillo, Part IV: Wine Faults and Me

It’s been about a year since I bottled my Tempranillo, and so I thought it was time to give it a try. This is a wine I had great hopes for: I had participated in a tasting at WineMaker magazine’s conference last year, and the wine had received reviews that ranged from the merely positive to almost glowing. And it had been in the bottle for only 35 days – hardly over bottle shock.

So you can imagine my surprise when, almost immediately after opening the bottle, I detected an odor – not an aroma, mind you, but an odor. I thought perhaps that it was just one of those things – a little, well, I don’t know what. I just thought it would pass.

It didn’t.

I poured the wine, swirled it vigorously, and sniffed. It stunk.

And then I swirled the glass much longer and even more vigorously, and sniffed again. It still stunk.

Well, I thought, perhaps it’s one of those wines with barnyard or some such aromas but wonderful tastes. I think there are such things. Well, actually, I have no idea. I was just hoping.

But if there are such things, they didn’t account for this bottle’s problems. It tasted just awful. I suppose that if I were a still a college student, more interested in the alcohol content than the aromas and taste of the wine, I could have choked it down. I’m sure I drank much worse in those days. (Remember Ripple? Boone’s Farm?)

But today? No, no way. I would say that in an even more emphatic way, but this is a family friendly blog and such language is not permitted.

I can’t begin to tell you how depressed I was beginning to feel. This was my prize wine, the star of all the wines I have made, and I had outrageously outsized expectations for it. And yet, the evidence was clear. It stunk.

That was especially bad news now, since I’m getting ready for our first grape harvest in a couple of months. If my very best effort with a kit wine had turned out so badly, how could I possibly expect to do well with fresh fruit, which is a much more complicated process.

I decided I would give the bottle another day, so I set it aside and opened a California Pinot Noir to drink instead.

The next night, I opened the Tempranillo again, more in fear than anticipation, and quickly realized my instincts were right. It still stunk. Probably as much as the first night, maybe more. Now I was really depressed.

But a day later, on the way into work, I suddenly realized that I recognized that bottle’s foul smell. TCA taint. The wine was corked. I was sure of it.

A corked bottle is one that has been tainted by 2,4,6-Trichloroanisole, or TCA for short. It’s usually described as smelling like a damp basement or wet socks left too long in the hamper. Over the years, I’ve read that something like one to five bottles out of every hundred suffer from TCA taint. I actually find that hard to believe, since I rarely encounter one. In fact, I have to say that the only reason I recognized this flaw as TCA taint is because I took a class last year on wine faults and had an opportunity to sniff and taste a corked wine.

Even so, I clearly wasn’t prepared to believe that a wine I had made and bottled could possibly be corked. The idea hadn’t even entered my head.

A tale of two bottles. They came out of the same tank, made in exactly the same way, but one was a joy to drink, and the other sucked!

But this evening, energized by this flash of insight, I pulled out another bottle of the same Tempranillo to taste. I have to say, I was a bit concerned – clearly, my bottling technique could use some work because there was at least an extra inch of air in the neck of the bottle. Well, that’s why I’m working with kits: trying to get all the mistakes out of my system.

Opening the new bottle, I was prepared for the worst. But after pulling the cork, I sniffed the wine from the bottle and was thrilled – no sign of TCA! I poured a half-glass, swirled, sniffed and was elated. The wine was definitely not corked. But was it good?

I tasted it, and wanted to shout. Yes, indeed, it was good. Soft tannins, big fruit, nice acidity. I’m guessing that Robert Parker won’t be including it in the next issue of the Wine Advocate, but whether it warrants a score of 92 or 82, it was good – a lovely, drinkable wine.

So, I’m somewhat more confident about my prospects as a winemaker. And, as a bonus, I have another two cases of good wine that I don’t have to pour down the drain.

A final word. I think everyone who loves wine should feel comfortable returning a bottle and telling a waiter at a restaurant or the manager at a wine store that the wine is flawed. I’ve done this perhaps a half-dozen times in my life. And at Total Wines, for example, they never bat an eye. They take the bottle and invite me to get another. And I suppose they would offer me a refund, but I’ve never asked. It seems more fair to get another bottle of the same wine.

And that’s the point. If you buy a wine, you should be prepared to deal with it. If you decide it’s not to your taste, ok, you won’t be buying it again. But you shouldn’t think you’re entitle to a refund because you like soft tannins and the wine you bought needs a couple of years in the cellar. Or because you bought a white that was aged in oak and you suddenly realize that you prefer whites aged in stainless.

But a genuine fault is different. If the wine is corked or oxidized, if it has severe Brettanomyces, then you should feel comfortable in sending in back. It’s not always an easy call. It took me two days to realize my wine was corked. And Brettanomyces? Well, that’s a touchy subject. A little can add some character, more than that can ruin the wine.

So, I guess the best advice I can offer is to trust your instincts, but be reasonable. And over time, if you taste enough wine, you’ll learn to recognize common wine faults. Which, thank God, are few and far between these days.

Sampling Wine Across Europe

We’ve visited a lot of wine regions over the past 20 years or so, but as our interest in viticulture and winemaking has grown, we’ve begun looking at vineyards and wineries with new eyes. That was especially the case on our most recent vacation, where we visited Venice, London, and Bordeaux. Especially Bordeaux. But I’ll get to that later.

While we enjoyed the winery visits we made in years past, it was a different kind of enjoyment from today. Then, we would taste wine in

Sonoma or Napa or some other wine valley, and buy a bottle or two to take home. Sometimes we might hire a limo or go in a van or micro bus tour with other couples, and those were great times that I wouldn’t trade away for anything.

Today, though, we are as interested in what goes on behind the scenes – in the vineyard and in the cellar – as we are in tasting the wine. Actually, they’ve become related pursuits. When we visit wineries, ideally we’d like to look at the vines and talk to vineyard managers about the soil, the climate and all of the other things that make their wine special. We want to see the cellar and the barrel rooms (although I sometimes feel that when you’ve seen one barrel room, you’ve seen them all), and we want to talk to the winemaker about the vintages we’re going to taste, the challenges that they faced in each of those years, and the approach they take to making the wine. And then, of course, we want to taste, but only after we know something about the vines and cellar practices.

That’s the ideal; the reality usually falls a bit short. Actually, it usually falls a lot short. Most tasting rooms in the United States are staffed by novices with limited knowledge of the wines they’re pouring, and it’s rare to find a winery where we can see the vineyard and talk to someone who knows anything at all about the vines. Of course, there have been days when we’ve been able to realize that ideal. And a week ago, in Bordeaux, we hit the mother lode.

First things first, though. We had decided to start our trip in Venice, where we thought we’d relax and adjust to European time in a leisurely way. And truthfully, we just love Italy in general and Venice in particular. This trip, we decided to go for a change in scenery by staying in Murano, a small island that is perhaps a 20 minute vaporetto (water bus) ride from Venice.

On our second day, we ventured over to Burano, an island known for lace and, for us, the scene of some of the most memorable meals of our lives. As it happens, Burano is connected by a bridge to another small island – Mazzorbo – and on Mazzorbo, there is a small restaurant and inn with a vineyard. The vineyard is just over two hectares in size, and it is entirely surrounded by medieval walls that were rebuilt in 1727. According to the web site, the vines are mostly ungrafted, which means they are growing on their own roots, rather than on an American rootstock that is immune from phylloxera, the aphid-like insect that nearly destroyed the European wine industry in the 19th century.

Old as the walls are, the vineyard itself was planted just three years ago, the same year that we planted our own small hobby vineyard. So, of course we were interested in comparing notes with the vineyard manager. Alas, this is one of those times where our expectation fell short of reality. We had the opportunity to wander through the vineyard, but unfortunately, the restaurant and tasting room were closed for an event, and most of the folks we hoped to talk to were missing. Well, maybe next time.

But it’s pretty hard to be unhappy in Italy. We had a number of great meals and some lovely wine. And there’s something special about walking around under the Italian sun.

London didn’t afford us any opportunities to visit wineries, but between the British museum, the British Library, Kensington Palace and the wonderful London theater, we had some good meals and good wine. And we did enjoy several wine bars. One was the “Green Man and French Horn,” a bar that specializes (exclusively) in wines from the Loire Valley. I found that surprising. I suspect most people don’t know Loire Valley wines very well, if at all, and I didn’t know much about most of the wines on the list. But there were some familiar wines, especially the Chinon, which are based on Cabernet Franc, and the Viognier. Both grapes, by the way, do exceptionally well in Virginia, and we have both growing in our own vineyard.

Our favorite wine bar, though, was “The Ten Cases,” which serves a dozen or so different wines, but orders just ten cases of each. Once those ten cases are finished, the wine is gone from this bar forever, and ten cases of a different wine are ordered in its place. We loved the food, and loved the wine. If we lived in London’s Convent Garden area, where it’s located, I suspect we would dine there on the order of once a week.

After London, we moved on to Bordeaux, which was something quite special. Our apartment looked out over the ancient city gate, the Porte de Bourgogne, and the Garonne River. Inside, there was a small wine rack on the wall with four bottles of Bordeaux. The information folder explained that some guests arrive too late to be able to purchase wine; in those cases, they should open the bottle of their choice and replace it with another. The bottles weren’t terribly exciting – Bordeaux Superieur, for example – but I’m sure they were fine. As it happened, we didn’t arrive too late to purchase wine of our own, and I opted for an inexpensive St. Emilion to keep handy for a late afternoon- early evening glass on our terrace. I think I might have paid a grand total of 9 Euros for it, and it was delicious.

On our first day, still tired from waking at 3:30 a.m. in London to get to Gatwick for an early flight, we wandered through the town center, and sat down at a small café for some wine and cheese. I believe the wine was a Pauillac, and it set the pattern: we didn’t have one bad glass of wine the entire visit.

But it’s one thing to enjoy a bottle of wine at a restaurant, wine bar or tasting room, and quite another to get outside the city and tour the great wine estates. We did both, and I’ll focus on the estates we visited in my next post.

If we’re winter pruning, then Spring must be close

Maintaining a vineyard is a year-round enterprise. Even in the winter, after the vines go into a dormant state, there’s work to be done. In fact, dormant winter pruning is among the most time-consuming work of the year, and some of the most important as well, since it involves decisions that will affect not just the coming season’s growth, but the year after as well.

Most of the objectives of dormant pruning fall under the heading of “balance.” Vines will grow just fine on their own, with no pruning at all, but most of their energy will go toward producing shoots and leaves, rather than grapes. Absent any intervention, the vines will continue to grow skyward for so long as they can find support. The whole purpose of a trellis system and the pruning decisions that go with it are to force the vine to direct its energy toward the production of high-quality fruit rather than vegetative growth.

So we’re looking for balance as we decide which shoots and how many buds to retain. Prune away too much and the vine will be undercropped, producing less fruit than it can reasonably support. Prune away too little and it will be overcropped, producing a profusion of leaves and shoots, as well as an abundance of fruit that is destined to be of low quality.

During the growing season, we’ll drop some fruit from the vine, again to direct energy toward the remaining clusters in the hopes of producing more concentrated and higher-quality grapes. But the first decisions we make that will determine the quantity and quality of the season’s fruit are those made in the dead of winter.

Which is to say, when it’s cold outside. Really, really cold. Not to mention snowing every few days or so. (Or maybe it just seemed that way this winter.) Which is one of the reasons we’ve put off pruning.

The other, more noble reason for delaying our pruning, has to do with timing. It’s better not to prune too early in the season – the untouched vines will survive a cold spell much better than those that have been pruned back, and by waiting, you’ll have more options in the case of a late freeze that damages buds and shoots.

It’s helpful to be able to assess the vine late in the winter for cold injury before deciding which canes to remove and which few to retain. In our little hobby vineyard, we have the luxury of delaying for almost as long as we want to start dormant pruning. Commercial vineyards that have acres of vines to prune, don’t have that luxury. They need to start early enough to be able to finish the job before budbreak. But many vineyards employ a technique of double pruning, going through once early in the winter to trim away the shoots they know won’t be used, and returning later to finish up the job.

This cane-pruned vine is finished on the left arm, only partly done on the right. Click on the picture for a better view.

Our vines are all trained to a trellis system known as vertical shoot positioning, of VSP, and we have adopted a pruning method known as cane pruning. In cane pruning, most of the previous year’s growth is pruned away, and two one-year old shoots, which have now achieved the status of canes, are retained and trained in either direction along the bottom, or fruiting wire. These canes – the one-year old wood – will give rise to new shoots this summer, and these new shoots are the part of the vine that will bear fruit.

At the same time, we’ll be looking for renewal spurs below this year’s fruiting canes. These will be pruned back to one or two buds to provide the fruiting canes for the following year.

I’ve taken a class or two on pruning, and I’ve done lots of reading and studied more videos on the Internet than I can count. So, of course, I should be an expert. And in theory I am. I know a lot about the why’s and how’s of pruning. But the actual pruning – the time when you come face to face with a vine and decide what to lop off and what to keep – that’s a whole different story. I still remember my first pruning session. I was sure that I was going to destroy the vine, and I stared at it for what seemed like hours before I worked up the nerve to make that initial cut. I’ve gotten a little more confident, but only a little. I still spend way too much time on each vine. Fortunately, we only have 230 vines now, so I can get away with it.

When the Vineyard Goddess and I got out a few weeks ago – and yes, we chose a weekend when the temperatures were in the 60s – we realized that we had not maintained the vines as well as we should have in the previous year. No neglect, just the kinds of mistakes you make early on. A number of the vines were just fine, but others lacked the kind of year-old shoots we were looking for to train to the cordon wire.

So, we made some adjustments. On the vines that had perfect one-year old shoots, we cut away everything else and tied these canes down. On those that didn’t, we resorted to a different pruning method called spur or cordon pruning.

In spur pruning, a cordon is tied down to the wire and used year after year. The shoots from the previous year are pruned down to two buds, which will give rise to fruitful wood for the current season. It’s more like a haircut, and most people would say it’s a far easier method of pruning than cane pruning. And it works well for at least the first decade. At some point, however, these cordons grow thick from age and produce fewer spurs. Moreover, they’re more prone to disease. It’s the same with people. The older you get, the more opportunity your body has to develop diseases.

Which method is better? Well, they each have advantages and disadvantages. Jim Law, founder and owner of Linden Vineyards, said he started with spur pruning, which worked well for years, but eventually moved to cane pruning, after the disadvantages – disease in particular – began to outweigh the advantages.

Our thought, however, is that we’ll spur prunes those vines that need it this year, while leaving some buds that we hope will give rise to canes that can be trained to the wire in 2015. And while I remain hopeful that our vines will produce some wonderful fruit thisyear for making wine, I am confident that we’ll do even better next year and better still in each of the succeeding years. After all, this is a learning experience, and Lord knows, we’re learning.

Recent Comments